Turnkey Projects

Complete End-to-End Packing Solutions for Turnkey Projects

Industry Overview

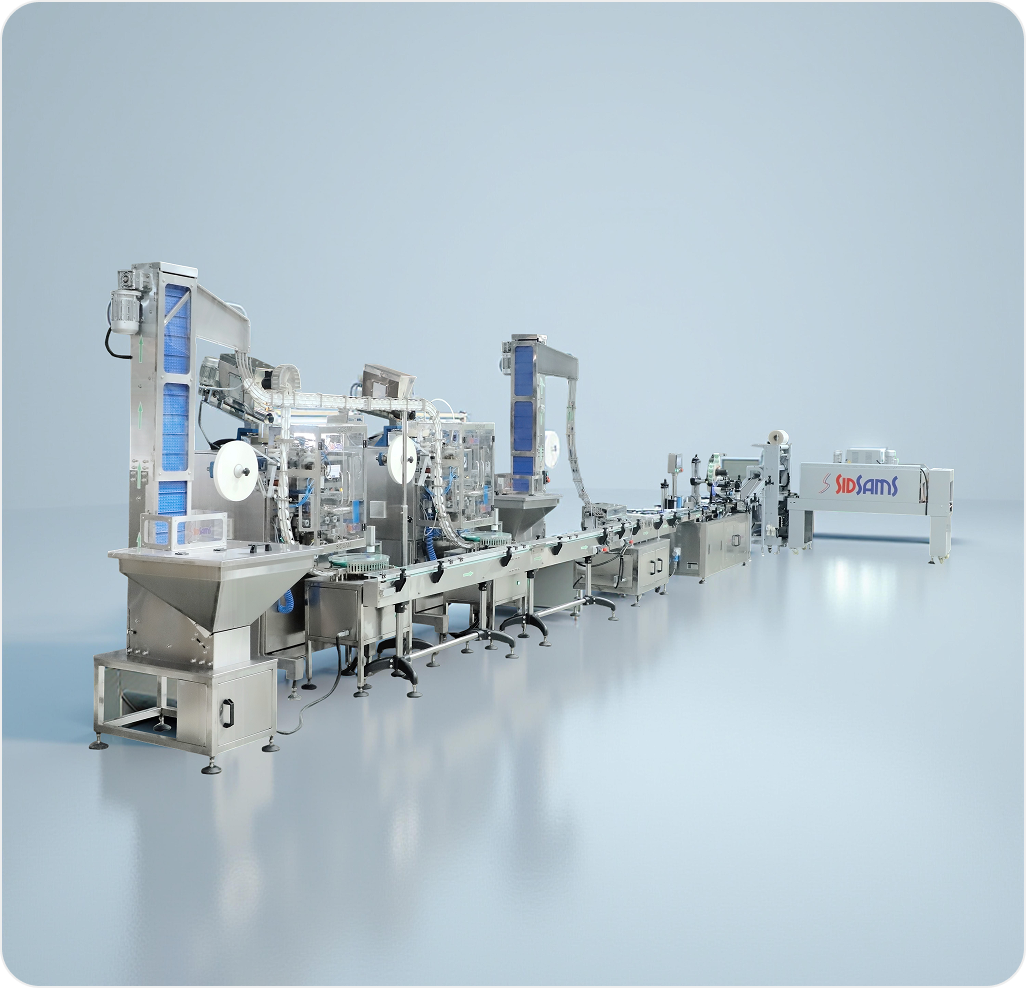

Turnkey Packing Projects by SidSam Group

From initial concept to commissioning, we take full responsibility for your packing setup – ensuring seamless workflow, precision automation and long-term operational excellence.

Our turnkey systems are widely used across industries such as Nicotine & Snus, Pharmaceuticals, Food & Beverage, Cosmetics and Industrial Goods, delivering superior speed, efficiency and reliability.

Our Range of Machines for Turnkey Projects

Automatic Nicotine/Caffeine/ Tobacco Snus Packing Plant for Cans

A high-precision single chamber tea bag packing machine with outer sachet, designed for fast, hygienic and aroma-protected tea packing.

Key Features :

- Inner tea bag + outer sachet in one machine

- Consistent weighing and filling accuracy

- Heat-sealed envelope for freshness

- Food-grade stainless-steel build

- Compact, low-maintenance system

Automatic Nicotine/Caffeine/ Tobacco Snus Packing Plant for Sachet

High-speed single-chamber tea bag packing machine with heat-sealable outer sachet for efficient, precise and hygienic packing.

Key Features :

- High-speed output for bulk tea bag production

- Heat-sealable outer sachet for secure packing

- Accurate filling for consistent tea weight

- Compact design with low maintenance

- Ideal for food & beverage manufacturing lines

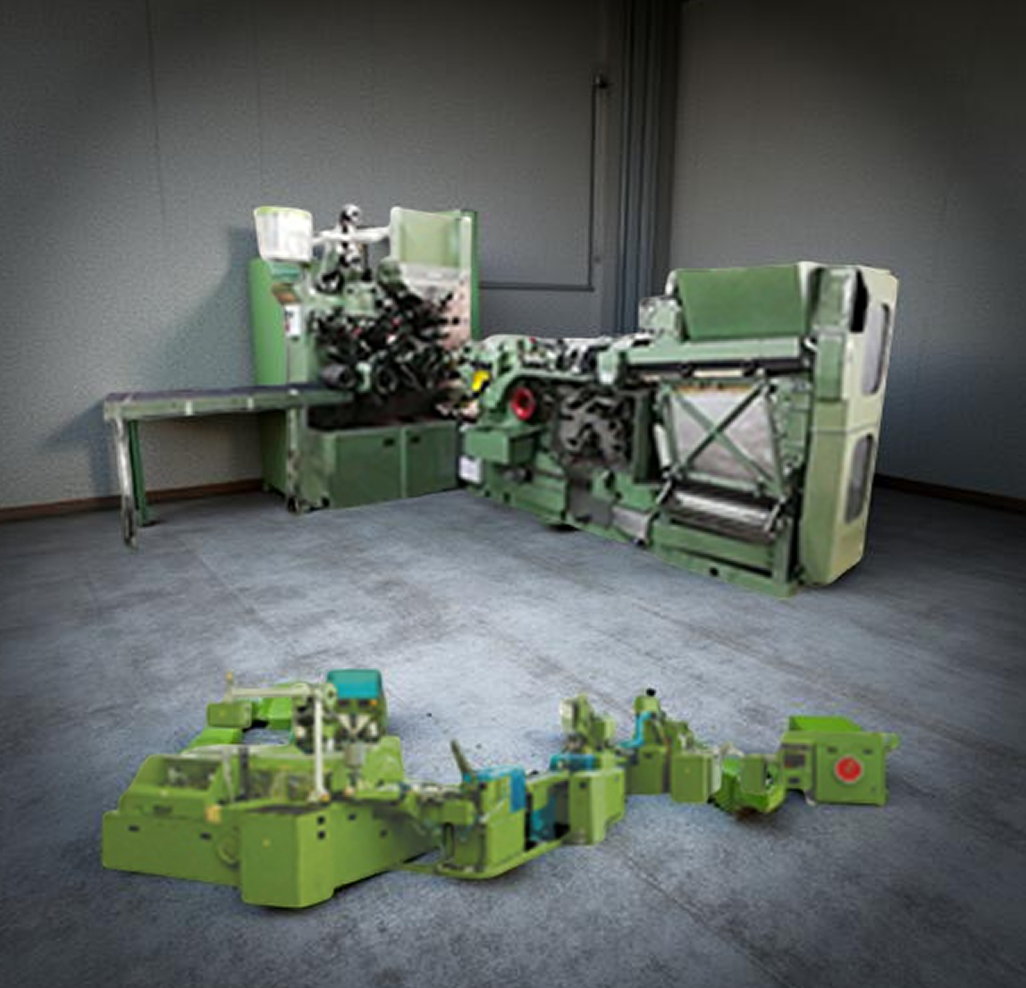

Automatic High-Speed Cigarette Making and Packing Plant for Carton Boxes

High-speed single-chamber tea bag machine with a paper-crimped outer envelope for clean, premium tea packing.

Key Features :

- Paper-crimped outer pack

- High-speed automated output

- Precise dosing accuracy

- Food-grade, hygienic build

- Compact & low-maintenance

Automatic Loose Tobacco / Loose Snus Packing Plant for Cans

Pyramid Tea Bag Packing Machine with an outer sachet system for premium, aromatic, high-quality tea packing.

Key Features :

- Pyramid-shape nylon/mesh tea bags

- Outer sachet for enhanced freshness

- High-precision weighing & sealing

- Smooth, fully automatic operation

- Ideal for premium & herbal teas

Complete Line Automation Solutions

SidSam Group’s turkey solutions combine precision machinery with intelligent control systems to create continuous, automated packing lines for every industry.

VFFS Systems

Vertical Form Fill Seal systems for high-speed pouch and sachet production with precision forming and sealing.

Flow Wrap Machines

Horizontal flow wrap systems for product wrapping with automatic feeding and cutting mechanisms.

Multihead Weigher Systems

High-accuracy weighing and filling systems for precise product dosing and portion control.

Pouch Sealing Units

Advanced sealing technology for pouches, sachets and container filling with quality inspection.

Carton packing systems

Our carton packing systems provide fast, precise and reliable packing performance while ensuring smooth, efficient operations.

Shrink wrapping & bundling machines

Our shrink wrapping and bundling machines deliver secure, high-speed packing for stable, professional product presentation.

Tray or case packers

Our tray and case packers ensure efficient, accurate and secure product placement for streamlined end-of-line packing.

Conveyor integration

Our conveyor integration solutions enable smooth, continuous product flow for faster, more efficient production lines.

Labeling, printing and coding

Our labeling, printing and coding solutions deliver precise, high-quality product identification for seamless production and compliance.

Inspection and rejection units

Our inspection and rejection units ensure accurate quality checks and remove non-compliant products to maintain a flawless production line.

Robotic pick & place automation

Our robotic pick & place automation delivers fast, precise and reliable product handling to boost efficiency and consistency in your production line.

Precision-Engineered for Continuous, High-Speed Operation

Each component is designed and synchronized to ensure uninterrupted output, high-speed performance and consistently low downtime – even in demanding environments. Built for modern production lines, it delivers stable efficiency, reduced maintenance and long-term operational reliability.

What is a Turnkey Packing Project?

A turnkey project means you get a complete packing solution – designed, built, installed and tested – all under one roof. You receive a ready-to-run setup that includes all machines, conveyors, accessories and integration software to start production immediately.

Project Planning & Design

Complete layout design and feasibility analysis tailored to your facility

System Integration

Electrical automation and PLC-based control with SCADA monitoring

Installation & commissioning

Full on-site setup with testing and optimization for peak performance

Operator Training

Comprehensive training programs for your production team

Quality Assurance

GMP, CE and ISO-certified manufacturing processes

Maintenance Support

Ongoing technical support and spare parts availability

Single Source of Accountability

You get a fully functional production line without coordination hassles between multiple vendors. SidSam Group takes full responsibility from concept to commissioning, ensuring seamless workflow, precision automation and long-term operational excellence.

Our Project Capabilities

SidSam Group’s expertise in mechanical design, PLC automation and material handling ensures the perfect synchronization between all machines in a production line.

Line Capacity Planning

Feasibility analysis and capacity optimization for your production requirements

Custom Packing Design

Pouch layout support and packing material specifications

System Integration

Integration with existing machines or third-party systems

PLC Control Panels

Full electrical and PLC-based control with advanced automation

SCADA Monitoring

Real-time data control and production monitoring systems

HMI Interface

Centralized operator-friendly control for easy operation

Industries We Serve with Turnkey Projects

SidSam Group has successfully executed turnkey projects for a wide range of sectors:

Tobacco & Snus

Snus portioning lines and Swedish Snus automatic pouch packing machines (our core specialization).

Pharma & Healthcare

Portion packs and pouching solutions for syringes, medical equipment, medical powders, supplements.

Food & Beverage

Packing for snacks, dairy products, sauces, pulses, confectionery, tea, sugar, ready-to-eat items.

Personal Care & Cosmetics

Packing solutions for lotions, creams, gels, shampoos, ointments and similar toiletries.

Industrial Goods

Packing for auto parts, pet food agrochemicals, lubricants, adhesives, paint and powders.

Each project is built to match your factory layout, production volume, and packing material specifications.

Advantages of SidSam Turnkey Solutions

Every SidSam machine is designed according to international standards, ensuring safe and standardized operations across industries

- One-Stop Partner

Single-source accountability for the entire project from machine design to final installation.

- Reduced Setup Time

Ready-to-run lines with pre-tested integration save months of coordination and downtime.

- Optimized Productivity

Every machine is configured to work at synchronized speeds for maximum output.

- Quality & Compliance

Manufactured under GMP, CE and ISO-certified processes to ensure global standard compliance.

- Scalable & Modular

Easily upgradeable to add new product formats, filling types or secondary Packing systems.

- After-Sales Support

Complete maintenance, spare parts and on-site training for uninterrupted performance.

Recent Turnkey Projects Delivered

SidSam Group has successfully executed numerous projects globally, demonstrating engineering capability, innovation and commitment to performance

- Sweden

- 2025

Complete Snus in Can Filling Line

A fully automated setup for fast, accurate snus can filling and finishing.

Precision Filling

Clean Labeling

Secure Sealing

High-Speed Conveying

- India

- 2025

Complete Caffeine in Can Filling Line

A fully automated system for fast, accurate caffeine pouch can filling.

Precision Filling

Clean Labeling

Secure Sealing

High-Speed Conveying

- UAE

- 2025

Complete Loose Tobacco in Can Filling Line

A fully automated line designed for loose-tobacco filling, secure sealing.

Precision Filling

Smooth Labeling

Tight Sealing

High-Speed Conveying

- Europe

- 2025

Complete Nicotine in Can Filling Line

A fully automated system engineered for nicotine can filling, secure sealing.

Precision Filling

Smooth Labeling

Reliable Sealing

High-Speed Conveying

Turnkey Solutions

These turnkey solutions demonstrate SidSam Group’s engineering capability, innovation and commitment to performance.

Future-Ready Packing Automation

SidSam turnkey solutions are built not just for today but for the future of manufacturing

Sustainable Solutions

SidSam turnkey projects incorporate eco-efficient, recyclable materials and energy-optimized control

systems.

Eco-Efficient Materials

Recyclable materials compatibility

Energy Optimized

Energy-optimized control systems

Lower

Carbon Footprint

Eco

Materials

Energy

Efficient

Smart Factories

We’re driving the shift toward smart factories through IoT-based monitoring, predictive maintenance and real-time production analytics.

IoT-Based Monitoring

Real-time production tracking

Predictive Maintenance

AI-driven maintenance scheduling

Production Analytics

Real-time performance analytics

Better Traceability

Complete production tracking

- India

- 2025

Complete Caffeine in Can Filling Line

A fully automated system for fast, accurate caffeine pouch can filling.

Precision Filling

Clean Labeling

Secure Sealing

High-Speed Conveying

- UAE

- 2025

Complete Loose Tobacco in Can Filling Line

A fully automated line designed for loose-tobacco filling, secure sealing.

Precision Filling

Smooth Labeling

Tight Sealing

High-Speed Conveying

- Europe

- 2025

Complete Nicotine in Can Filling Line

A fully automated system engineered for nicotine can filling, secure sealing.

Precision Filling

Smooth Labeling

Reliable Sealing

High-Speed Conveying

Global Support Network

We provide installation, training and after-sales support globally. Our technical team ensures your packing line runs efficiently, helping you maintain uninterrupted production and consistent packing quality.

Get in Touch

Looking to start or scale your production and packing line with a complete turnkey solution?

📞 Contact SidSam Group today to explore customized, fully automated and end-to-end turnkey solutions for tobacco, pharmaceuticals, personal care, food & beverages and industrial goods.

E-mail us

sales@sidsamgroup.com info@sidsamgroup.com

Call us

+91 8368599034,

+91-9811986899

Address

14/7, Mathura Rd,

Faridabad, HR (INDIA)

Find Your Answers Here

Couldn’t not find what you were looking for?

write to us at info@sidsamgroup.com

Lorem Ipsum has been the industry's ?

Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially

Lorem Ipsum has been the industry's ?

Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially

Lorem Ipsum has been the industry's ?

Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially

Lorem Ipsum has been the industry's ?

Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially